About us.

Zhang Siming: Adhere to a rigorous attitude to restore real data

Classification: Employee Style

Release time: 2024-12-30

Summary: "There is a kind of happiness, which is doing what you like and are good at." This happy big boy is named Zhang Siming, representing the outstanding employees of the company born in the 1990s.

"There is a kind of happiness that comes from doing what you love and are good at." This happy young man is Zhang Siming, a representative of the company's outstanding "post-90s" employees. He is taciturn and even possesses a maturity and steadiness that is not in line with his actual age. In 2014, after graduating from Changchun University of Science and Technology with a degree in Chemical Engineering and Technology, he plunged into the QC testing laboratory of Jilin Aolide. Over the course of five years, he has consistently used a rigorous attitude to restore real data, completing a remarkable transformation from a theoretical learner to a practical skill creator.

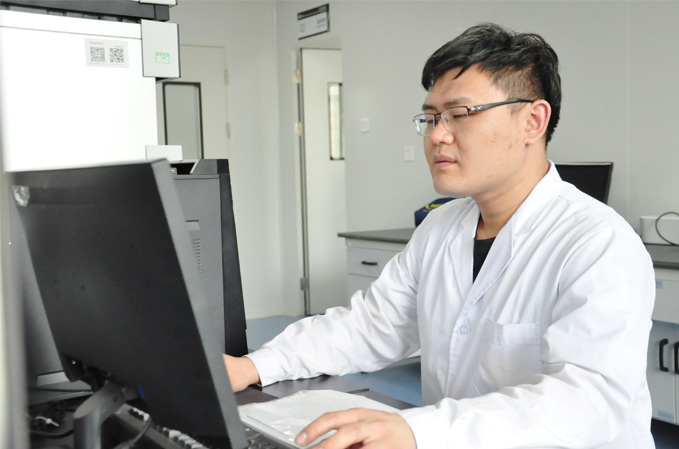

HPLC data processing

Persisting in rigor and restoring the truth is Zhang Siming's work principle. The QC testing position he holds is responsible for the dual testing tasks of incoming raw materials and outgoing finished products, where the accuracy of data directly affects the company's product quality and process requirements, allowing no room for carelessness or errors. During his years at Aolide, he transformed from a naive newcomer who always intended to reduce testing processes into a meticulous and rigorous master. When strictness and norms become a work habit, and hard training brings practical experience, the accuracy and truth of data are maximally guaranteed, and the QC testing team has never faced quality disputes due to inaccurate data delivery.

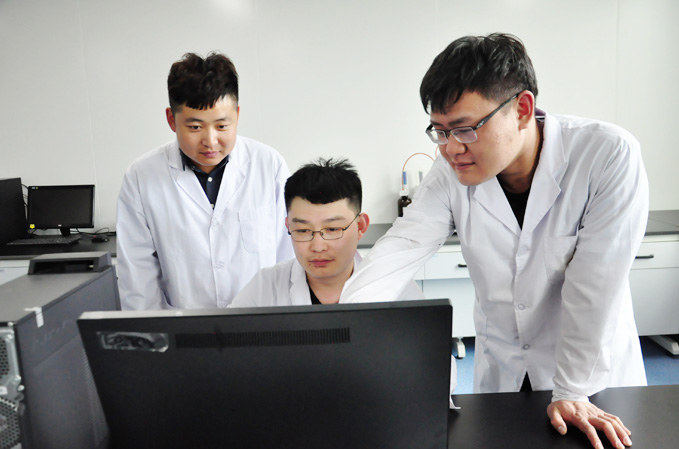

Guiding team members in data processing

"A gentleman is not a tool." Being knowledgeable and versatile is the source of Zhang Siming's continuous learning and progress. In the QC testing team, various commonly used equipment such as liquid chromatographs, gas chromatographs, DSC, and TG are neatly arranged; these are their tools and partners. When these partners have a "headache" or "catch a cold" during their day and night work, the testing work must stop and wait for the manufacturer's technician to come for repairs. Sometimes the wait can last one or two days, which can be quite frustrating. This made Zhang Siming determined to learn the daily maintenance and repair skills of testing equipment, no matter how difficult it may be. When the manufacturer's technician comes to repair the equipment, he is particularly enthusiastic, closely observing and learning. He also reviewed a large number of equipment user manuals and maintenance guides, and with the strong support of the company, he participated in training sessions organized by equipment suppliers multiple times, quickly becoming a versatile technician. He learns while working and works while learning; under Zhang Siming's leadership, every team member learns technology and becomes proficient with the equipment. Now, the daily maintenance of QC testing equipment and the replacement of commonly used consumables are basically resolved within the team, saving the company a significant amount in equipment repair costs while greatly improving work efficiency, ensuring the timely completion of several urgent and difficult testing tasks for the company.

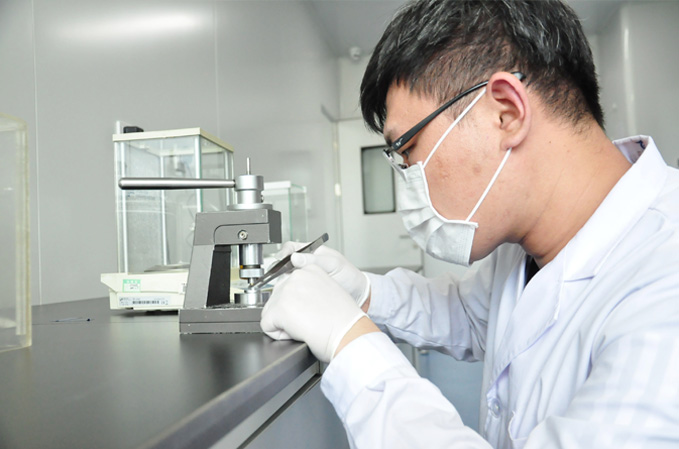

DSC sample tablet pressing

In the minds of most people, testing work requires sitting still and enduring loneliness. However, Zhang Siming does not find his work boring at all; more often, he is in a state of excitement. As Zhang Siming's leader and teacher, Quality Inspection Department Manager Zhao He commented on him: "He loves his work and is truly very suitable for this position." It is this love for his profession that allows him to continuously fight on the testing front during the most demanding month of testing tasks, helping the company to expedite the development and production of new products; it is this love for work that has enabled him and his colleagues to complete the compilation of inspection specifications for various raw materials and products over the past three years.300Compilation of inspection specifications for various raw materials,100and the compilation of inspection specifications for various products; it is also this selfless love for the company and the position that has earned him unanimous praise from various departments and downstream manufacturers for his high-quality and efficient testing services.

Zhang Siming feels very lucky because he has entered the OLED industry, a sunrise industry, and has climbed onto the shoulders of domestic industry giants. The innovative development platform provided by Jilin Aolide will allow young people like him in the company to stand at the forefront of domestic industry technology. When talking about future goals, he said: "If the inspection specifications of Aolide can becomeOLEDthe industry standard, it would be the greatest affirmation of the company's testing technology and capabilities."

Key words: Zhang Siming: Adhere to a rigorous attitude to restore real data